(A) Alloy and non-alloy elements

Carbon steel wire has almost non-alloy elements mainly for C, Si, Mn, S, and P.

However, stainless steel wire has various alloy elements especially for Cr and Ni that occupy 12% Minimum in percentage.

Various chemical elements lead to large discrepancy on mechanical property and working process for final use.

(B) Corrosion resistance

Carbon steel wire apparently shows weak anti-corrosion ability due to its higher carbon component. In order to avoid any rust, slushing oil is necessarily in conventional use for un-galvanized carbon wires during storage and transportation.

On the other hand, stainless steel wire has quite stronger anti-corrosion ability to meet market consumption, especially for SS 300 series.

(C) Magnetism

Carbon steel wire possesses obviously strong magnetism. Stainless steel wire has none or weak magnetism for both SS 200 series and 300 series, but there is distinct magnetism for SS 400 series on account of its martensitic structure.

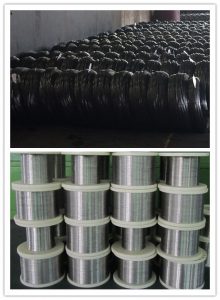

(D) Wire surface

Carbon steel wire surface is normally black and shiny, however stainless steel wire is always in silver bright color (Some part of SS wires with dull surface for special application) due to its abundant alloy elements involved, as well as its clearly smooth surface.