- brass coated steel wire in drawing

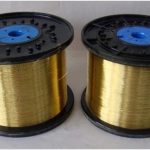

- brass coated steel wire in spool

- brass coated steel wire in pallet

Summary:

Brass coated steel wire for rubber hose reinforcement is widely used for high pressure rubber hose products.

Brief Introduction:

Brass coated steel wire for rubber hose reinforcement is sort of high carbon steel wire with carbon content approximately 0.70%-0.90% in percentage. Brass coated steel wire has the brass content of 68%±4% and zinc content of 32%±4%, which lead to good adhesive force to rubber hose and rich flexibility as well as its high tensile strength. Due to its specific features, brass coated wire is qualified to apply for various industrial fields, such as high pressure rubber hose, hydraulic machine, oil filed drilling machine, coal mining machine, engineering machine, oil transportation system and etc. Besides, brass coated steel wire brush for various purposes are also made of that wire and enjoyed popularity in market.

Brass coating process is simply illustrated as followed: quench – water cooling – water washing – pickling+alkali washing+water washing – brass coating – pure water washing – zinc coating – pure water washing – hot water washing – spread(brass coating & zinc coating) – pickling – water washing – drying – wire collection.

Brass coated steel wire has two kind of delivery states in shape after process, one is round wire and the other is flat wire. In addition that, there are four grades of tensile strength, LT(low tensile), NT(normal tensile), HT(high tensile) and ST(super tensile)

Brass coated steel wire manufacturers in China are located in east part of country from the south up to the north. Brass coated steel wire price in market is certain different from company to company on account of brass coating quality control, wire drawing technology and final package for rust protection.

- brass coated steel wire for hydraulic hose

- brass coated steel wire for braided sleeving

- brass coated steel wire for brush

Brass coated steel wire for rubber hose reinforcement

Apply for mechanical, mining equipment, constructional and metallurgical industry

Standard: GB/T 11182-2017; ISO23717:2006

ROUND WIRE

| DIA (MM) | T/S (MPA) | TORSION PER TIME (MIN) | BENDING PER TIME (MIN) | KNOT STRENGTH RATIO % (MIN) |

|---|---|---|---|---|

| 0.2 | 2150-2450 (LT) | 70 | 125 | 58 |

| 2450-2750 (NT) | 70 | 125 | 58 | |

| 2750-3050 (HT) | 65 | 125 | 56 | |

| 3050-3350 (ST) | 60 | 110 | 54 | |

| 0.25 | 2150-2450 (LT) | 70 | 125 | 58 |

| 2450-2750 (NT) | 70 | 125 | 58 | |

| 2750-3050 (HT) | 65 | 105 | 56 | |

| 3050-3350 (ST) | 60 | 75 | 54 | |

| 0.28 | 2150-2450 (LT) | 70 | 125 | 58 |

| 2450-2750 (NT) | 70 | 125 | 58 | |

| 2750-3050 (HT) | 65 | 105 | 56 | |

| 3050-3350 (ST) | 60 | 75 | 54 | |

| 0.295 | 2150-2450 (LT) | 65 | 105 | 58 |

| 2450-2750 (NT) | 60 | 95 | 58 | |

| 2750-3050 (HT) | 60 | 85 | 56 | |

| 3050-3350 (ST) | 50 | 60 | 54 | |

| 0.3 | 2150-2450 (LT) | 65 | 105 | 58 |

| 2450-2750 (NT) | 60 | 95 | 58 | |

| 2750-3050 (HT) | 60 | 85 | 56 | |

| 3050-3350 (ST) | 50 | 60 | 54 | |

| 0.35 | 2150-2450 (LT) | 65 | 60 | 58 |

| 2450-2750 (NT) | 60 | 60 | 58 | |

| 2750-3050 (HT) | 60 | 55 | 56 | |

| 3050-3350 (ST) | 50 | 50 | 54 | |

| 0.38 | 2150-2450 (LT) | 65 | 60 | 58 |

| 2450-2750 (NT) | 60 | 60 | 58 | |

| 2750-3050 (HT) | 60 | 55 | 56 | |

| 3050-3350 (ST) | 50 | 45 | 54 | |

| 0.4 | 2150-2450 (LT) | 65 | 55 | 58 |

| 2450-2750 (NT) | 60 | 55 | 58 | |

| 2750-3050 (HT) | 60 | 55 | 56 | |

| 3050-3350 (ST) | 50 | 45 | 54 | |

| 0.45 | 2150-2450 (LT) | 60 | 45 | 58 |

| 2450-2750 (NT) | 60 | 45 | 58 | |

| 2750-3050 (HT) | 50 | 40 | 56 | |

| 0.5 | 2150-2450 (LT) | 60 | 40 | 55 |

| 2450-2750 (NT) | 60 | 35 | 55 | |

| 2750-3050 (HT) | 50 | 30 | 55 | |

| 0.56 | 2150-2450 (LT) | 60 | 35 | 55 |

| 2450-2750 (NT) | 60 | 30 | 55 | |

| 2750-3050 (HT) | 50 | 25 | 55 | |

| 0.6 | 2150-2450 (LT) | 60 | 30 | 55 |

| 2450-2750 (NT) | 50 | 25 | 55 | |

| 2750-3050 (HT) | 40 | 20 | 55 | |

| 0.65 | 2150-2450 (LT) | 55 | 25 | 55 |

| 2450-2750 (NT) | 50 | 20 | 55 | |

| 2750-3050 (HT) | 40 | 18 | 55 | |

| 0.7 | 2150-2450 (LT) | 50 | 20 | 55 |

| 2450-2750 (NT) | 50 | 20 | 55 | |

| 2750-3050 (HT) | 45 | 18 | 55 | |

| 0.75 | 2150-2450 (LT) | 50 | 20 | 55 |

| 2450-2750 (NT) | 50 | 20 | 55 | |

| 0.78 | 2150-2450 (LT) | 40 | 15 | 55 |

| 2450-2750 (NT) | 40 | 15 | 55 | |

| 0.8 | 2150-2450 (LT) | 40 | 15 | 55 |

| 2450-2750 (NT) | 30 | 15 | 55 | |

| 1 | 1770-1860 (LT) | 25 | 14 | — |

| 1860-1950 (NT) | 23 | 14 | — | |

| 1950-2150 (HT) | 20 | 14 | — | |

| 1.2 | 1770-1860 (LT) | 25 | 14 | — |

| 1860-1950 (NT) | 24 | 14 | — | |

| 1950-2150 (HT) | 23 | 14 | — | |

| 1.4 | 1770-1860 (LT) | 24 | 14 | — |

| 1860-1950 (NT) | 23 | 14 | — | |

| 1950-2150 (HT) | 22 | 14 | — | |

| 1.6 | 1770-1860 (LT) | 23 | 13 | — |

| 1860-1950 (NT) | 20 | 13 | — | |

| 1950-2150 (HT) | 19 | 13 | — | |

| 1.8 | 1770-1860 (LT) | 22 | 12 | — |

| 1860-1950 (NT) | 20 | 12 | — | |

| 1950-2150 (HT) | 19 | 12 | — | |

| 2 | 1770-1860 (LT) | 20 | 10 | — |

| 1860-1950 (NT) | 20 | 10 | — | |

| 1950-2150 (HT) | 19 | 10 | — | |

| 2.2 | 1770-1860 (LT) | 18 | 10 | — |

| 1860-1950 (NT) | 18 | 10 | — | |

| 1950-2150 (HT) | 17 | 10 | — | |

| 2.4 | 1770-1860 (LT) | 18 | 10 | — |

| 1860-1950 (NT) | 18 | 10 | — | |

| 1950-2150 (HT) | 17 | 10 | — |

LT=Low Tensile

NT=Normal Tensile

HT=High Tensile

ST=Super Tensile

FLAT WIRE

| SPECIFICATION B X H (MM) | T/S (MPA) |

|---|---|

| 0.30 X 0.18 | 2750-3050 (HT) |

| 3050-3350 (ST) | |

| 0.35 X 0.22 | 2750-3050 (HT) |

| 3050-3350 (ST) | |

| 0.40 X 0.25 | 2750-3050 (HT) |

| 3050-3350 (ST) | |

| 0.44 X 0.28 | 2750-3050 (HT) |

| 3050-3350 (ST) | |

| 0.54 X 0.34 | 2450-2750 (NT) |

| 2750-3050 (HT) | |

| 0.59 X 0.38 | 2450-2750 (NT) |

| 2750-3050 (HT) | |

| 0.81 X 0.55 | 2150-2450 (LT) |

| 2450-2750 (NT) |

B=Breadth

H=Height

Brass coated steel wire in drawing