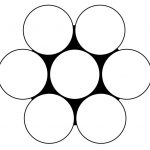

- steel wire rope 1X7

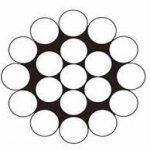

- steel wire rope 1X19

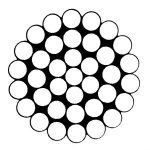

- steel wire rope 1X37

- steel wire rope 1X7-illustration

- steel wire rope 1×19-illustration

- steel wire rope 1 x 37-illustration

Steel wire rope for vehicle

Steel wire rope used for vehicle also as called as vehicle steel wire rope, is widely applied for important vehicle units such as hand brake detent, accelerator detent, clutch detent, damper detent, door & window detent, fuel tank cap detent, and yacht, ship, airplane involved similarly.

Vehicle steel wire rope should be conventionally coated by solid polymer such as PE, PP, PA, PTFE, FEP and PFA, which is definitely not allowed to use reworked material but the qualified fresh. There is a variety of classification of material for vehicle wire rope, carbon steel and stainless steel. Vehicle wire rope is the certain special rope and we give an illustration as follow to clarify its specific mark. “CS 6X7+IWS 1770 zS PA 1.5/1.0 BK GB/T 36131-2018″, CS=carbon steel; 6X7+IWS=rope construction with strand core; 1770=Tensile strength 1770mpa; zS=twist direction of strand(S) and rope(Z); PA=coating material; 1.5=diameter of coated rope; 1.0=diameter of uncoated rope; BK=coating color is black; GB/T36131-2018=the specified China standard.

Vehicle steel wire rope should be in straight and unloose state for delivery. There should be not allowed that any greasy dirt attached to the surface of rope since it may cause chemical reaction to plastic coating. Further wire welding is also strictly prohibited for vehicle wire rope. During the anti-aging test for plastic coating, any crack and chap should not be accepted yet. Detailed requirement against anti-aging test for various plastic coating should be confirmed before order.

Vehicle steel wire rope is effectively used as essential units for automobile manufacturing as it has continued to grow at faster rate. Vehilce steel wire strand of 1X7, 1X19 and 1X37 worked as important and irreplaceable material in automobile is a strong, sturdy and reliable alternative that can be safely relied on.

STEEL WIRE ROPE – STRAND

Apply for vehicle & automobile

Standard: EN12385; GB/T20118-2006; GB/T36131-2018

Construction: 1X7

| Rope Diameter (mm) | Weight (kg/100m) | T/S (mpa) | |||

|---|---|---|---|---|---|

| 1570 | 1670 | 1770 | 1870 | ||

| Minimum Breaking Load (kn) | |||||

| 0.6 | 0.19 | 0.31 | 0.32 | 0.34 | 0.36 |

| 1.2 | 0.75 | 1.22 | 1.3 | 1.38 | 1.45 |

| 1.5 | 1.17 | 9.91 | 2.03 | 2.15 | 2.27 |

| 1.8 | 1.69 | 2.75 | 2.92 | 3.1 | 3.27 |

| 2.1 | 2.3 | 3.74 | 3.98 | 4.22 | 4.45 |

| 2.4 | 3.01 | 4.88 | 5.19 | 5.51 | 5.82 |

| 2.7 | 3.8 | 6.18 | 6.57 | 6.97 | 7.36 |

| 3 | 4.7 | 7.63 | 8.12 | 8.6 | 9.09 |

| 3.3 | 5.68 | 9.23 | 9.82 | 10.4 | 11 |

| 3.6 | 6.77 | 11 | 11.7 | 12.4 | 13.1 |

| 3.9 | 7.94 | 12.9 | 13.7 | 14.5 | 15.4 |

| 4.2 | 9.21 | 15 | 15.9 | 16.9 | 17.8 |

| 4.5 | 10.6 | 17.2 | 18.3 | 19.4 | 20.4 |

| 4.8 | 12 | 19.5 | 20.8 | 22 | 23.3 |

| 5.1 | 13.6 | 22.1 | 23.6 | 24.9 | 26.3 |

| 5.4 | 15.2 | 24.7 | 26.3 | 27.9 | 29.4 |

| 6 | 18.8 | 30.5 | 32.3 | 34.4 | 36.4 |

| 6.6 | 22.7 | 36.9 | 39.3 | 41.6 | 44 |

| 7.2 | 27.1 | 43.9 | 46.7 | 49.5 | 52.3 |

| 7.8 | 31.8 | 51.6 | 54.9 | 58.2 | 61.4 |

| 8.4 | 36.8 | 59.8 | 63.6 | 67.4 | 71.3 |

| 9 | 42.7 | 68.7 | 73 | 77.4 | 81.8 |

| 9.6 | 48.1 | 78.1 | 83.1 | 88.1 | 93.1 |

| 10.5 | 57.6 | 93.5 | 99.4 | 105 | 111 |

| 11.5 | 69 | 112 | 119 | 126 | 134 |

| 12 | 75.2 | 122 | 130 | 138 | 145 |

Total Breaking Load = Rope Minimum Breaking Load X 1.111

CONSTRUCTION: 1X19

| Rope Diameter (mm) | Weight (kg/100m) | T/S (mpa) | |||

|---|---|---|---|---|---|

| 1570 | 1670 | 1770 | 1870 | ||

| Minimum Breaking Load (kn) | |||||

| 1 | 0.51 | 0.83 | 0.89 | 0.94 | 1.99 |

| 2 | 2.03 | 3.33 | 3.54 | 3.75 | 3.96 |

| 3 | 4.56 | 7.49 | 7.97 | 8.44 | 8.92 |

| 4 | 8.11 | 13.3 | 14.2 | 15 | 15.9 |

| 5 | 12.7 | 20.8 | 22.1 | 23.5 | 24.8 |

| 6 | 18.3 | 30 | 31.9 | 33.8 | 35.7 |

| 7 | 24.8 | 40.8 | 43.4 | 46 | 48.6 |

| 8 | 32.4 | 53.2 | 56.6 | 60 | 63.4 |

| 9 | 41.1 | 67.4 | 71.7 | 76 | 80.3 |

| 10 | 50.7 | 83.2 | 88.6 | 93.8 | 99.1 |

| 11 | 61.3 | 101 | 107 | 114 | 120 |

| 12 | 73 | 120 | 127 | 135 | 143 |

| 13 | 85.7 | 141 | 150 | 158 | 167 |

| 14 | 99.4 | 163 | 173 | 184 | 194 |

| 15 | 114 | 187 | 199 | 211 | 223 |

Total Breaking Load = Rope Minimum Breaking Load X 1.111

CONSTRUCTION: 1X37

| Rope Diameter (mm) | Weight (kg/100m) | T/S (mpa) | |||

|---|---|---|---|---|---|

| 1570 | 1670 | 1770 | 1870 | ||

| Minimum Breaking Load (kn) | |||||

| 1.4 | 0.98 | 1.51 | 1.6 | 1.7 | 1.8 |

| 2.8 | 3.93 | 6.03 | 6.42 | 6.8 | 7.18 |

| 3.5 | 6.14 | 9.42 | 10 | 10.6 | 11.2 |

| 4.9 | 12 | 18.5 | 19.6 | 20.8 | 22 |

| 5.6 | 15.7 | 24.1 | 25.7 | 27.2 | 28.7 |

| 7 | 24.5 | 37.7 | 40.1 | 42.5 | 44.9 |

| 8.4 | 35.4 | 54.3 | 57.7 | 61.2 | 64.7 |

| 9.8 | 48.1 | 73.9 | 78.6 | 83.3 | 88 |

| 11 | 60.6 | 93.1 | 99 | 105 | 111 |

| 12 | 72.1 | 111 | 118 | 125 | 132 |

| 14 | 98.2 | 151 | 160 | 170 | 180 |

| 17 | 145 | 222 | 236 | 251 | 265 |

| 18 | 162 | 249 | 265 | 281 | 297 |

| 21 | 221 | 339 | 361 | 382 | 404 |

Total Breaking Load = Rope Minimum Breaking Load X 1.176