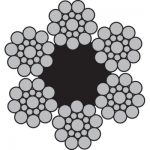

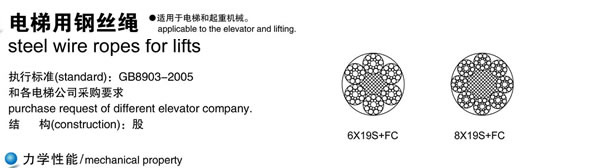

- steel wire rope 6x19S+FC

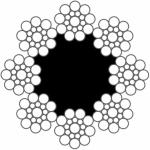

- steel wire rope 8x19S+FC

Steel wire rope for lifts & elevator called as elevator wire rope, is required higher demand on manufacturing tolerances and wire quality than other factors.

Elevator steel wire rope has a variety of two kind of tensile strength, one named as single tensile rope and the other dual tensile rope. For single tensile rope, the inner layer and the outer layer steel wires both have the same tensile strength excepted for core wire and filler wire. However for dual tensile rope, the inner layer steel wire has the different tensile strength from that of outer layer steel wire, excepted for core wire and filler wire also. For instance, if the elevator steel wire rope shows tensile strength of 1370/1770mpa and that means outer layer wire’s T/S is 1370mpa but inner layer wire’s T/S is 1770mpa.

Elevator steel wire rope core includes firber core and wire core. Fiber core covers synthetic fiber core and nature fiber core respectively, meanwhile IWRC, IWSC and CSC are involved as wire core. (IWRC=Independent wire rope core; IWSC=Independent wire strand core; CSC=composite synthetic core)

Elevator steel wire rope should be delivered by ungalvanized or galvanized state as required. Especially for galvanized rope there is a definitely demand that all wires in rope should be galvanzied. For the elongation rate of elevator rope, there is specified in China standard that fiber core rope’s structural elongation should be 0.60% maximum with elastic elongation 0.20% maximum, and that wire core rope’s structural elongation 0.45% maximum with elastic elongation 0.15% maximum, provided special appointment available.

With high tensile strength and excellent ductility, elevator steel wire rope is conventionally designed for use in traction and deflection sheaves. Lubricating grease always plays key important role, since it can not only protect elevator wire rope from corrosion but also decrease the abrasion as maximum as possible wire to wire, strand to strand, wire to strand, strand to rope and rope to traction wheel. Lubricating grease is the really important and essential process for elevator rope. Keep frication and abrasioin as less as better is the right way to prolong the service life of elevator wire rope. As the fast technical progress, a newe style of elevator steel wire rope with high manganese content & good wear-resistance & sufficient phosphated coating appears in market due to its more excellent performance than the ordinaries.

Elevator steel wire rope should be stored in ventilated and dry space without rain, acid and alkali contact. As for use, the hoisting logo on the wooden reel should be the right indication to follow and simultaneously keep the packing reel always in good condition with less or no damage to rope.

6X19S+FC and 8X19S+FC are the typical construction of elevator steel wire rope in market with conventional diameter 10mm minimum, while this rope with diameter of 6mm and 8mm are commonly for auxiliary use.

STEEL WIRE ROPE

Apply for elevator & lift

Standard: ISO 4344:2004; GB/T8903-2005; GB/T8903-2018; GB/T8918-2006; GB/T20118-2006

Construction: 6X19S+FC; 8X19S+FC

| Rope Diameter (mm) | Weight (kg/100m) Natural Fiber Core | Minimum Breaking Strength (kn) | ||

|---|---|---|---|---|

| 1370/1770 (mpa) Double Strength | 1570(mpa) Single Strength | 1770(mpa) Single Strength | ||

| 6*19S+FC | ||||

| 6 | 12.9 | 17.8 | 18.7 | 21 |

| 8 | 23 | 31.7 | 33.1 | 37.4 |

| 10 | 35.9 | 49.5 | 51.8 | 58.4 |

| 11 | 43.4 | 59.9 | 62.7 | 70.7 |

| 13 | 60.7 | 83.7 | 87.6 | 98.7 |

| 16 | 91.9 | 127 | 1233 | 150 |

| 19 | 130 | 179 | 187 | 211 |

| 22 | 174 | 240 | 251 | 283 |

| 8*19S+FC | ||||

| 8 | 21.8 | 28.1 | 29.4 | 33.2 |

| 10 | 34 | 44 | 46 | 51.9 |

| 11 | 41.1 | 53.2 | 55.7 | 62.8 |

| 13 | 57.5 | 74.3 | 77.7 | 87.6 |

| 16 | 87 | 113 | 118 | 133 |

| 19 | 123 | 159 | 166 | 187 |

| 22 | 165 | 213 | 223 | 251 |

Total Breaking Load = Rope Minimum Breaking Load X 1.214(FC)