Steel wire rope for lifting machine and fish net dragging purposes is one sort of conventional ropes widely applied for infrastructure fields.

This steel wire rope is diveded into black(ungalvanized) and galvanized by surface state. For galvanization, there is grade A, AB and B the three zinc coating grades for choice. For galvanized rope, all the wires in the rope should be galvanized indeed. Fiber core(jute, saisal, cotton and synthetic fiber core) and wire core(IWRC and IWSC) are the primary kinds for the steel wire rope. Fiber core should be sufficiently dipped into lubricating grease aimed to corrosion and rust resistance. Steel wire rope surface should be evenly and completely applied for greased oil whatever ungalvanized or galvanized provided special appointment available.

Steel wire rope should be twisted tightly, balanced and unloose in manufacturing. Steel wire rope also should be no wave-shape as unrolled naturally without loading. Wires in the rope is not allowed to be crossed, bent and broken. Further each of lay length in the same steel wire rope should be almost alike without obvious discrepancy.

This steel wire rope should accept split test, which means that the rope needs seperated into stands and wires and then detected on each wire by various items, such as wire size, numbers, tensile strength, knot strength, bending, torsion and zinc coating test. For knot strength test, wire should achieve the knot tensile strength as 50% minimum as that of original without knot. Further, steel wire rope is required to involve the test of length, weight, surface, breaking load and unloose inspection.

Steel wire rope should be stored in ventilated and dry space without rain, acid and alkali contact. As for use, the hoisting logo on the wooden reel should be the right indication to follow and simultaneously keep the packing reel always in good condition with less or no damage to rope.

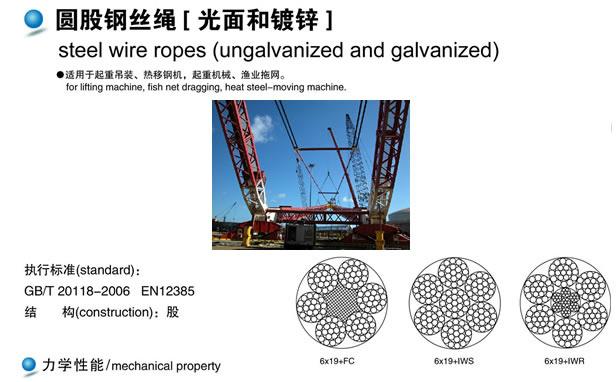

STEEL WIRE ROPE

Apply for lifting machine, fish net dragging and heat steel-moving machine

Standard: GBT/20118-2006 ; EN12385

Construction: 6*19+FC ; 6*19+IWS; 6*19+IWR

| Rope Diameter (mm) | Weight (kg/100m) | T/S (mpa) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1570 | 1670 | 1770 | 1870 | ||||||||

| Minimum Breaking Load (kn) | |||||||||||

| Natural fiber core | Synthetic fiber core | IWR/IWS | Natural fiber core | IWR/IWS | Natural fiber core | IWR/IWS | Natural fiber core | IWR/IWS | Natural fiber core | IWR/IWS | |

| 3 | 3.16 | 3.1 | 3.6 | 43.4 | 46.9 | 4.61 | 4.99 | 4.89 | 5.29 | 5.17 | 5.59 |

| 4 | 5.62 | 5.5 | 6.4 | 77.1 | 83.4 | 8.2 | 8.87 | 8.69 | 9.4 | 9.19 | 9.93 |

| 5 | 8.78 | 8.6 | 10 | 12 | 13 | 12.8 | 13.9 | 13.6 | 14.7 | 14.4 | 15.5 |

| 6 | 12.6 | 12.4 | 14.4 | 17.4 | 18.8 | 18.5 | 20 | 19.6 | 21.2 | 20.7 | 22.4 |

| 7 | 17.2 | 16.9 | 19.6 | 23.6 | 25.5 | 25.1 | 27.2 | 26.6 | 28.8 | 28.1 | 30.4 |

| 8 | 22.5 | 22 | 25.6 | 30.8 | 33.4 | 32.8 | 35.5 | 34.8 | 37.6 | 36.7 | 39.7 |

| 9 | 28.4 | 27.9 | 32.4 | 39 | 42.2 | 41.6 | 44.9 | 44 | 47.6 | 46.5 | 50.3 |

| 10 | 35.1 | 34.4 | 40 | 48.2 | 52.1 | 51.3 | 55.4 | 54.4 | 58.8 | 57.4 | 62.1 |

| 11 | 42.5 | 41.6 | 48.4 | 58.3 | 63.1 | 62 | 67.1 | 65.8 | 71.1 | 69.5 | 75.1 |

| 12 | 50.5 | 50 | 57.6 | 69.4 | 75.1 | 73.8 | 79.8 | 78.2 | 84.6 | 82.7 | 89.4 |

| 13 | 59.3 | 58.1 | 67.6 | 81.5 | 88.1 | 86.6 | 93.7 | 91.8 | 99.3 | 97 | 105 |

| 14 | 68.8 | 67.4 | 78.4 | 94.5 | 102 | 100 | 109 | 107 | 115 | 113 | 122 |

| 16 | 89.9 | 88.1 | 102 | 123 | 133 | 131 | 142 | 139 | 150 | 147 | 159 |

| 18 | 114 | 111 | 130 | 156 | 169 | 166 | 180 | 176 | 190 | 186 | 201 |

| 20 | 140 | 138 | 160 | 193 | 208 | 205 | 222 | 217 | 235 | 230 | 248 |

| 22 | 170 | 166 | 194 | 233 | 252 | 248 | 268 | 263 | 284 | 278 | 300 |

| 24 | 202 | 198 | 230 | 278 | 300 | 295 | 319 | 313 | 338 | 331 | 358 |

| 26 | 237 | 233 | 270 | 326 | 352 | 346 | 375 | 367 | 397 | 388 | 420 |

| 28 | 275 | 270 | 314 | 378 | 409 | 402 | 435 | 426 | 461 | 450 | 487 |

| 30 | 316 | 310 | 360 | 434 | 469 | 461 | 499 | 489 | 529 | 517 | 559 |

| 32 | 359 | 352 | 410 | 494 | 534 | 525 | 568 | 557 | 602 | 588 | 636 |

| 34 | 406 | 398 | 462 | 557 | 603 | 593 | 641 | 628 | 679 | 664 | 718 |

| 36 | 455 | 446 | 518 | 625 | 676 | 664 | 719 | 704 | 762 | 744 | 805 |

| 38 | 507 | 497 | 578 | 696 | 753 | 740 | 801 | 785 | 849 | 829 | 896 |

| 40 | 562 | 550 | 640 | 771 | 834 | 820 | 887 | 869 | 940 | 910 | 993 |

| 42 | 619 | 607 | 706 | 850 | 919 | 904 | 978 | 959 | 1040 | 1010 | 1100 |

| 44 | 680 | 666 | 774 | 933 | 1010 | 993 | 1070 | 1050 | 1140 | 1110 | 1200 |

| 46 | 743 | 728 | 846 | 1020 | 1100 | 1080 | 1170 | 1150 | 1240 | 1210 | 1310 |

Total Breaking Load = Rope Minimum Breaking Load x 1.226(FC) or 1.321 (IWR/IWS)