- steel wire rope 6X7+FC

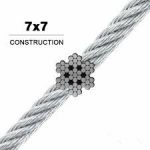

- steel wire rope 7X7

- steel wire rope 6X19+FC

- steel wire rope 7X19

Steel wire rope for aircraft control is widely used in areospace field, especailly for controling the rudder, aileron, engine, landing gear, compass corrector and such important units. Steel wire rope for aircraft also as called as aircraft wire rope, is definitely required to work for long-term under safety with higher performance than ordinary steel wire rope. As Standard specified, the breaking load of the weared parts shoud be 50% minimum as original rope load after exact fatigue test. In addtion that, aircraft wire rope should have strong corrosion resistance, because there is constantly lots of dew on the surface of wire rope during high-altitute fly in great changing atmosphere, and which can result in apperance of rusty. Further, as plane landing and braking, the engine has to oppositely spray flue gas which can easily cause violent pollution and corrosion on wire rope. As above, galvanized steel wire rope or stainless steel wire rope is the right workable choice applied for aircraft wire rope only. For galvanized steel wire rope, there are three grades of galvanization for choose by standard, which list as grade B, grade AB and grade A. For stainless steel wire rope, it is right to choose SS300 series such as SS302,SS304 and SS316 by various requirement.

Aircraft wire rope has such typical constructions as 1×7, 1×19, 6×7+IWS(7X7), 6×19+IWS(7X19), 6×7+NF and 6×19+NF. Among of them, 1X7 and 1X19 are both single strands, while 7X7 means 7 strands with 7 wires in each strand, and 7X19 means 7 strands with 19 wires in each strand. The more number of wires in a strand or cable of a given diameter, the more flexibility it has. Aircraft wire rope designed with 6X7+FC, 7×7, 6X19+FC and 7xl9 construction provide for increasing degrees of flexibility but decreased abrasion resistance by a given size. Those designs would be incorporated where continuous flexing is a requirement and such typical applications include aircraft control, farm machinery and automobiles.

To manufacture the qualified aircraft wire rope, the low tempering treatment is necessarily demanded for wire rope in order to release the stress in stranding and hydrogen in galvanization, and finally improve the fatigue performance and breaking load of rope.

STEEL WIRE ROPE – AIRCRAFT WIRE ROPE

Apply for major machinery and equiment of aircraft control

Standard: YB/T5197-2005; GB/T8918-2006; GB/T20118-2006

Construction: 6X7+FC, 6X7+IWS(7X7), 6X19+FC, 6X19+IWS(7X19)

| Rope Diameter (mm) | Allowed tolerance (%) | T/S (mpa) | Minimum Breaking Load (kn) | Approximate Weight (kg/100m) |

|---|---|---|---|---|

| 6*7+FC | ||||

| 1.8 | 10 | 1960 | 2.3 | 1.4 |

| 2.15 | 1960 | 3.3 | 2 | |

| 2.5 | 1960 | 4.5 | 2.7 | |

| 3.05 | 8 | 1870 | 6.3 | 4 |

| 3.6 | 1870 | 8.7 | 5.5 | |

| 4.1 | 7 | 1770 | 10.4 | 7 |

| 4.5 | 1770 | 12.8 | 8.7 | |

| 5.4 | 1670 | 17.5 | 12.5 | |

| 6*7+IWS | ||||

| 1.8 | 10 | 1870 | 2.5 | 1.5 |

| 2.15 | 1870 | 3.6 | 2.2 | |

| 2.5 | 1870 | 5 | 3 | |

| 3.05 | 8 | 1870 | 7.3 | 4 |

| 3.6 | 1870 | 10.1 | 6.2 | |

| 4.5 | 7 | 1770 | 15 | 9.6 |

| 5.4 | 1670 | 20.4 | 13.8 | |

Total Breaking Load = Rope Minimum Breaking Load X 1.134(FC) or 1.214 (IWR/IWS)

| Rope Diameter (mm) | Allowed tolerance (%) | T/S (mpa) | Minimum Breaking Load (kn) | Approximate Weight (kg/100m) |

|---|---|---|---|---|

| 6*19+FC | ||||

| 3 | 8 | 2060 | 6.3 | 3.8 |

| 3.3 | 2060 | 6.5 | 4.5 | |

| 3.6 | 2060 | 7.8 | 5.4 | |

| 4.2 | 1770 | 10.6 | 7.4 | |

| 4.8 | 1770 | 12.9 | 9 | |

| 5.1 | 7 | 1770 | 15.6 | 10.9 |

| 6.2 | 1670 | 20.3 | 15 | |

| 6*19+IWS | ||||

| 3 | 8 | 2060 | 7.3 | 4.2 |

| 3.2 | 2160 | 8.9 | 4.3 | |

| 3.6 | 2160 | 9.1 | 6 | |

| 4.2 | 7 | 2160 | 12.3 | 8.2 |

| 5.1 | 1770 | 18.2 | 12.1 | |

| 6 | 1770 | 23.7 | 16.7 | |

| 7.5 | 1770 | 37.1 | 26 | |

| 8.25 | 1670 | 44.9 | 32 | |

| 9 | 5 | 1670 | 53.4 | 37.6 |

| 9.75 | 1670 | 62.6 | 44.1 | |

Total Breaking Load = Rope Minimum Breaking Load X 1.226(FC) or 1.321 (IWR/IWS)