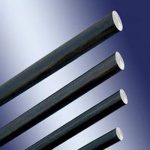

- pc wire – plain round wire

- pc wire – indented wire

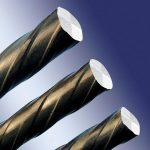

- pc wire – spiral rib wire

Summary:

PC wire (Prestressed concrete wire) and PC strand (prestressed concrete strand) are the important material widely used in various industrial fields especially for infrastructure sectors.

Brief Introduction:

PC wire & PC strand (Prestressed concrete wire & strand) are broadly required and used in reinforcement of prestressed concrete structures, such as large-span bridges, overhead crane beam, railway sleepers, cement poles, prefabricated floor slabs & pipes, foundations, coal mines, stadiums, dams, multi-story buildings, nuclear power projections and etc.

PC wire is one sort of high carbon steel wire with carbon content of 0.65%-0.85% in percentage, and has the typical advantages of low relaxation, high tensile strength and excellent anti-fatigue characteristic, which lead to the applied structures in perfect performance and maximum safety. Just due to the various feartures, PC wire is divided into multiple series products, such as cold drawn wire, tempered & straightened wire, low relaxtion wire, galvanzied wire, indented wire and etc.

PC wire by cold drawn is generally used in railway sleeper and concrete with sizes of 3.0mm-5.0mm. Cold drawn PC wire is required by tempering treatment, when the lead temperature should be 460-500 in centigrade and wire temperature 890-930 in centigrade. Followed by tempering, the wire tensile strength should be 1100mpa-1200mpa and the metallographic structure changed into Sorbite which could be greatly helpful for further drawing after pickling and phosphating.

PC wire by tempered & straightened can get higher yield strength and relieve the stress as the termperature keeps 460-500 in cengtigrade.

PC wire with low relaxation as called stabilized PC wire is by tempering treatment under tension. After the stabilization, the wire extremity of elasticity and yiled strength both get improvement, meanwhile the wire stress relaxation rate greatly decreased.

PC wire by hot dip galvanization with zinc coating 250-350g per square meter can be applied for bridge cable, cesspit and such serious corrosive structures.

PC wire by indented treatment can be applied for concrete since it is able to improve its adhesive force with beton.

PC wire has a variety of three types in shape, plain round wires, spiral rib wires and indented wires, and accordingly to the PC strands construction of 1×2, 1×3, 1×7 and 1×19. For PC wire surface, there is a variety of delivery states, black(ungalvanzied) wire with anti-corrosion grease, pvc coated wire, hot dipped galvanized wire and Galfan(Zn-5%Al-rare earth alloy) coated wire.

PC wire and PC strand manufacturers are generally distributed in east China from the south up to the north. PC wire and PC strand price is mainly up to the technology variety and manufacturing standard.

- pc wire strand

- pc wire-spiral rib wire

- pc wire-plain round wire

PC wire (Prestressed concrete wire)

Apply for concrete, construction, electric power, bridge, mine and railway project

Standard: GB/T 5223-2014, GB/T5224-2014, ASTM-A416, BS 5896, JIS G3536, EN10138-3

Plain round wire (P)

Spiral rib wire (H)

Indented wire (I)

1) Initial tension should be 70-80% Maximum.

2) Relaxation rate on 1000 hours should be 2.5%-3.5% Maximum.

3) Elongation by GL=200MM Should be 3.5% Minimum.

| DIA(MM) | T/S(MPA) | FEATURED TENSION (MIN. KN) | OBJECTIVE TENSION (MAX. KN) | 0.2% YIELDING TENSION (MIN. KN) | BENDS TIMES/180D MIN. | BENDS RADIUS (MM) |

| 4 | 1470 | 18.48 | 20.99 | 16.22 | 3 | 10 |

| 4.8 | 1470 | 26.61 | 30.23 | 23.35 | 4 | 15 |

| 5 | 1470 | 28.86 | 32.78 | 25.32 | 4 | 15 |

| 6 | 1470 | 41.56 | 47.21 | 36.47 | 4 | 15 |

| 6.25 | 1470 | 45.1 | 51.24 | 39.58 | 4 | 20 |

| 7 | 1470 | 56.27 | 64.26 | 49.64 | 4 | 20 |

| 7.5 | 1470 | 64.94 | 73.78 | 56.99 | 4 | 20 |

| 8 | 1470 | 73.88 | 83.93 | 64.84 | 4 | 20 |

| 9 | 1470 | 93.52 | 106.25 | 82.07 | 4 | 25 |

| 9.5 | 1470 | 104.19 | 118.37 | 91.44 | 4 | 25 |

| 10 | 1470 | 115.45 | 131.16 | 101.32 | 4 | 25 |

| 11 | 1470 | 139.69 | 158.7 | 122.59 | — | — |

| 12 | 1470 | 166.26 | 188.88 | 145.9 | — | — |

| 4 | 1570 | 19.73 | 22.24 | 17.37 | 3 | 10 |

| 4.8 | 1570 | 28.41 | 32.03 | 25 | 4 | 15 |

| 5 | 1570 | 30.82 | 34.75 | 27.12 | 4 | 15 |

| 6 | 1570 | 44.38 | 50.03 | 39.06 | 4 | 15 |

| 6.25 | 1570 | 48.17 | 54.31 | 42.39 | 4 | 20 |

| 7 | 1570 | 60.41 | 68.11 | 53.16 | 4 | 20 |

| 7.5 | 1570 | 69.36 | 78.2 | 61.04 | 4 | 20 |

| 8 | 1570 | 78.91 | 88.96 | 69.44 | 4 | 20 |

| 9 | 1570 | 99.88 | 112.6 | 87.89 | 4 | 25 |

| 9.5 | 1570 | 111.28 | 125.46 | 97.93 | 4 | 25 |

| 10 | 1570 | 123.31 | 139.02 | 108.51 | 4 | 25 |

| 11 | 1570 | 149.2 | 168.21 | 131.3 | — | — |

| 12 | 1570 | 177.57 | 200.19 | 156.26 | — | — |

| 4 | 1670 | 20.99 | 23.5 | 18.47 | 3 | 10 |

| 5 | 1670 | 32.78 | 36.71 | 28.85 | 4 | 15 |

| 6 | 1670 | 47.21 | 52.86 | 41.54 | 4 | 15 |

| 6.25 | 1670 | 51.24 | 57.38 | 45.09 | 4 | 20 |

| 7 | 1670 | 64.26 | 71.96 | 56.55 | 4 | 20 |

| 7.5 | 1670 | 73.78 | 82.62 | 64.93 | 4 | 20 |

| 8 | 1670 | 83.93 | 93.98 | 73.86 | 4 | 20 |

| 9 | 1670 | 106.25 | 118.97 | 93.5 | 4 | 25 |

| 4 | 1770 | 22.25 | 24.76 | 19.58 | 3 | 10 |

| 5 | 1770 | 34.75 | 38.68 | 30.58 | 4 | 15 |

| 6 | 1770 | 50.04 | 55.69 | 44.03 | 4 | 15 |

| 7 | 1770 | 68.11 | 75.81 | 59.94 | 4 | 20 |

| 7.5 | 1770 | 78.2 | 87.04 | 68.81 | 4 | 20 |

| 4 | 1860 | 23.38 | 25.89 | 20.57 | 3 | 10 |

| 5 | 1860 | 36.51 | 40.44 | 32.13 | 4 | 15 |

| 6 | 1860 | 52.58 | 58.23 | 46.27 | 4 | 15 |

| 7 | 1860 | 71.57 | 79.27 | 62.98 | 4 | 20 |

PC strand (Prestressed concrete strand)

1) Initial tension should be 70-80% Maximum.

2) Relaxation rate on 1000 hours should be 2.5%-4.5% Maximum.

3) Elongation by GL=400MM Should be 3.5% Minimum.

| 1X2 | ||||

|---|---|---|---|---|

| DIA (MM) | T/S (MPA) | FEATURED TENSION (MIN. KN) | OBJECTIVE TENSION (MAX. KN) | 0.2% YIELDING TENSION (MIN. KN) |

| 8 | 1470 | 36.9 | 41.9 | 32.5 |

| 10 | 57.8 | 65.6 | 50.9 | |

| 12 | 83.1 | 94.4 | 73.1 | |

| 5 | 1570 | 15.4 | 17.4 | 13.6 |

| 5.8 | 20.7 | 23.4 | 18.2 | |

| 8 | 39.4 | 44.4 | 34.7 | |

| 10 | 61.7 | 69.6 | 54.3 | |

| 12 | 88.7 | 100 | 78.1 | |

| 5 | 1720 | 16.9 | 18.9 | 14.9 |

| 5.8 | 22.7 | 25.3 | 20 | |

| 8 | 43.2 | 48.2 | 38 | |

| 10 | 67.6 | 75.5 | 59.5 | |

| 12 | 97.2 | 108 | 85.5 | |

| 5 | 1860 | 18.3 | 20.2 | 16.1 |

| 5.8 | 24.6 | 27.2 | 21.6 | |

| 8 | 46.7 | 51.7 | 41.1 | |

| 10 | 73.1 | 81 | 64.3 | |

| 12 | 105 | 116 | 92.5 | |

| 5 | 1960 | 19.2 | 21.2 | 16.9 |

| 5.8 | 25.9 | 28.5 | 22.8 | |

| 8 | 49.2 | 54.2 | 43.3 | |

| 10 | 77 | 84.9 | 67.8 | |

| 1X3 | ||||

| DIA (MM) | T/S (MPA) | FEATURED TENSION (MIN. KN) | OBJECTIVE TENSION (MAX. KN) | 0.2% YIELDING TENSION (MIN. KN) |

| 8.6 | 1470 | 55.4 | 63 | 48.8 |

| 10.8 | 86.6 | 98.4 | 76.2 | |

| 12.9 | 125 | 142 | 110 | |

| 6.2 | 1570 | 31.1 | 35 | 27.4 |

| 6.5 | 33.3 | 37.5 | 29.3 | |

| 8.6 | 59.2 | 66.7 | 52.1 | |

| 8.74 | 60.6 | 68.3 | 53.3 | |

| 10.8 | 92.5 | 104 | 81.4 | |

| 12.9 | 133 | 150 | 117 | |

| 8.74 | 1670 | 64.5 | 72.2 | 56.8 |

| 6.2 | 1720 | 34.1 | 38 | 30 |

| 6.5 | 36.5 | 40.7 | 32.1 | |

| 8.6 | 64.8 | 72.4 | 57 | |

| 10.8 | 101 | 113 | 88.9 | |

| 12.9 | 146 | 163 | 128 | |

| 6.2 | 1860 | 36.8 | 40.8 | 32.4 |

| 6.5 | 39.4 | 43.7 | 34.7 | |

| 8.6 | 70.1 | 77.7 | 61.7 | |

| 8.74 | 71.8 | 79.5 | 63.2 | |

| 10.8 | 110 | 121 | 96.8 | |

| 12.9 | 158 | 175 | 139 | |

| 6.2 | 1960 | 38.8 | 42.8 | 34.1 |

| 6.5 | 41.6 | 45.8 | 36.6 | |

| 8.6 | 73.9 | 81.4 | 65 | |

| 10.8 | 115 | 127 | 101 | |

| 12.9 | 166 | 183 | 146 | |

| 1 X 3 (INDENTED) | ||||

| 8.7 | 1570 | 60.4 | 68.1 | 53.2 |

| 1720 | 66.2 | 73.9 | 58.3 | |

| 1860 | 71.6 | 79.3 | 63 | |

| 1X7 | ||||

| DIA (MM) | TENSILE STRENGTH (MPA) | FEATURED TENSION (MIN. KN) | OBJECTIVE TENSION (MAX. KN) | 0.2% YIELDING TENSION (MIN. KN) |

| 15.20 (15.24) | 1470 | 206 | 234 | 181 |

| 1570 | 220 | 248 | 194 | |

| 1670 | 234 | 262 | 206 | |

| 9.50 (9.53) | 1720 | 94.3 | 105 | 83 |

| 11.10 (11.11) | 128 | 142 | 113 | |

| 12.7 | 170 | 190 | 150 | |

| 15.20 (15.24) | 241 | 269 | 212 | |

| 17.80 (17.78) | 327 | 365 | 288 | |

| 18.9 | 1820 | 400 | 444 | 352 |

| 15.7 | 1770 | 266 | 296 | 234 |

| 21.6 | 504 | 561 | 444 | |

| 9.50 (9.53) | 1860 | 102 | 113 | 89.8 |

| 11.10 (11.11) | 138 | 153 | 121 | |

| 12.7 | 184 | 203 | 162 | |

| 15.20 (15.24) | 260 | 288 | 229 | |

| 15.7 | 279 | 309 | 246 | |

| 17.80 (17.78) | 355 | 391 | 311 | |

| 18.9 | 409 | 453 | 360 | |

| 21.6 | 530 | 587 | 466 | |

| 9.50 (9.53) | 1960 | 107 | 118 | 94.2 |

| 11.10 (11.11) | 145 | 160 | 128 | |

| 12.7 | 193 | 213 | 170 | |

| 15.20 (15.24) | 274 | 302 | 241 | |

| 1 X 7 (INDENTED) | ||||

| 12.7 | 1860 | 184 | 203 | 162 |

| 15.20 (15.24) | 260 | 288 | 229 | |

| 1 X 7 (COMPRESSED) | ||||

| 12.7 | 1860 | 208 | 231 | 183 |

| 15.20 (15.24) | 1820 | 300 | 333 | 264 |

| 18 | 1720 | 384 | 428 | 338 |

| 1 X 19 S (1+9+9) | ||||

| DIA (MM) | T/S (MPA) | FEATURED TENSION (MIN. KN) | OBJECTIVE TENSION (MAX. KN) | 0.2% YIELDING TENSION (MIN. KN) |

| 28.6 | 1720 | 915 | 1021 | 805 |

| 17.8 | 1770 | 368 | 410 | 334 |

| 19.3 | 431 | 481 | 379 | |

| 20.3 | 480 | 534 | 422 | |

| 21.8 | 554 | 617 | 488 | |

| 28.6 | 942 | 1048 | 829 | |

| 20.3 | 1810 | 491 | 545 | 432 |

| 21.8 | 567 | 629 | 499 | |

| 17.8 | 1860 | 387 | 428 | 341 |

| 19.3 | 454 | 503 | 400 | |

| 20.3 | 504 | 558 | 444 | |

| 21.8 | 583 | 645 | 513 | |

| 1 X 19 W (1+6+6/6) | ||||

| 28.6 | 1720 | 915 | 1021 | 805 |

| 1770 | 942 | 1048 | 829 | |

| 1860 | 990 | 1096 | 854 | |