Carbon steel wire is of non-alloy wire and its manufacturing technique is conventional as follows.

Sample:

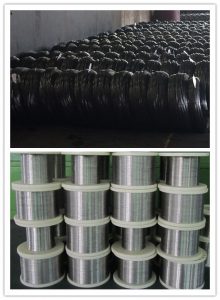

High carbon spring steel wire

Target wire size of 1.00mm with T/S 1960-2300 Mpa

Our essential process:

Step 1: Confirm the steel wire rods with grade of 70# or 72A# as customer required from China qualified steel plants.

Step 2: Confirm the former working process of annealing, patenting and phosphating are qualified for following wire drawing.

Step 3: Confirm the inlet wire diameter should be 3.10 mm, since the general compression ratio controlled in 90-95% is preferable for carbon spring wire.

Step 4: Confirm the dies in the tank with right sizes and rows of arrangement for wire drawing.

Step 5: The spring wire straightener should be installed in the wet wire drawing machine in order to achieve the perfect straightness circle.