OUR QUALITY IS YOUR TRUSTED SOURCE

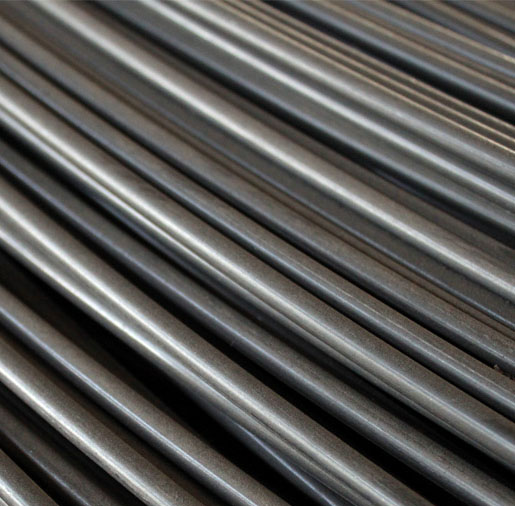

Steel wire quality control

full production process

from schedule till fulfilment

from wire rods till shipment

high carbon steel wire, stainless steel wire, galvanized wire, brass coated wire, low carbon steel wire, PC wire, ACSR core wire and more other purpose wire

with specialized wire knowledge

and high sense of responsibility

we provide superior wires to customers in the

spring, automotive, mechanical, hardware, construction, crane, grid and infrastructure sectors

Steel wire performance test

throughout manufacturing

for alloy & non alloy wire

size 0.10mm-12.0mm

on chemical component, wire surface, straightness, free circle & diameter, wire size & tolerance, coating, tensile strength, torsion, wrap, bending, packing weight, and others as customer required

Steel wire in spool

can be packed both in coil and in spool

stainless steel wire, brass coated wire, carbon steel wire and special purpose wire

spool size is up to wire size & customer requirement

spool material is primarily of plastic, steel and paperboard

wooden reel applied for steel wire rope

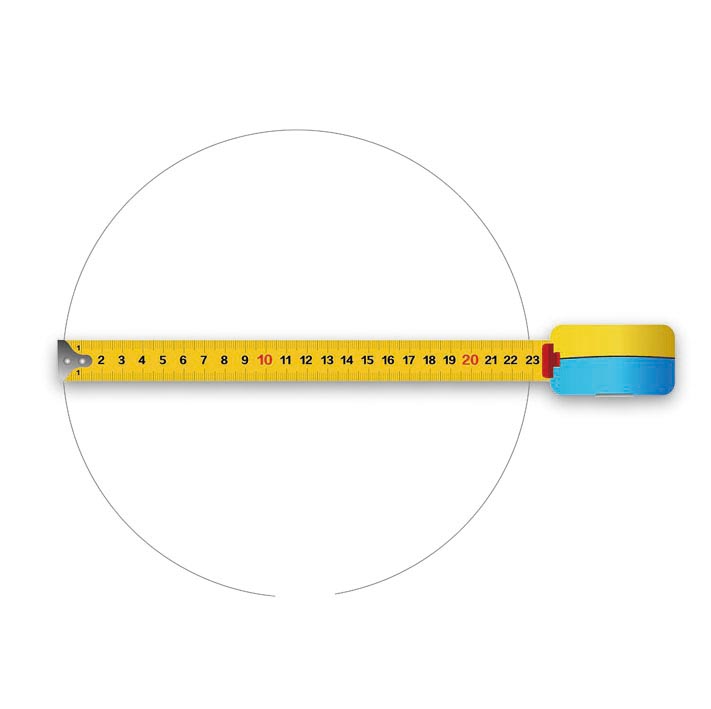

Steel wire straightness in circle

steel wire straightness in circle

steel wire size up to 0.50mm Max

standard pitch require 60mm Max

our QC system require 10mm Max

wire size 0.55mm-1.00mm

standard pitch require 80mm Max

our QC system require 10mm Max

same exacting demands on followed bigger sizes

higher demand for higher quality

Steel wire in free circle

standard free circle diameter

180mm - 300mm for wire in coil

150mm - 400mm for wire in spool

our QC system require 200-300mm

or as customer requirement

higher demand for higher quality

Steel wire diameter tolerance

standard diameter tolerance

0.195mm-0.205mm

our QC system require

0.195mm-0.200mm

same exacting demands on followed bigger sizes

higher demand for higher quality

Wet steel wire drawing machine

wire with high T/S

M/C model 150#/200# for Dia 0.10-0.25mm,

M/C model 250# for Dia 0.25-0.65mm

M/C model 350# for Dia 0.70-1.30mm

M/C model 450# for Dia 1.35-1.60mm

M/C model 560# for Dia 1.70-2.60mm

SS wire hydrogen annealing

to relieve stress, decrease hardness and eliminate irregularity of inner structure

but can effectively improve malleability, elongation, fatigue resistance & surface quality

in favour of followed application

and further wire drawing

Steel wire in annealing, patenting and galvanizing

for carbon steel wire

to decrease the brittleness, hardness & impurity

to turn wire metallographical structure into

soxtenite state

to effectively improve wire malleability, elongation and toughness

in favor of followed application

and further wire drawing

We Up Steel Wire

INTRODUCTION

We are specialized company engaged in manufacturing and exporting steel wire, rope & machinery with technical support since 2005.

PRODUCTS

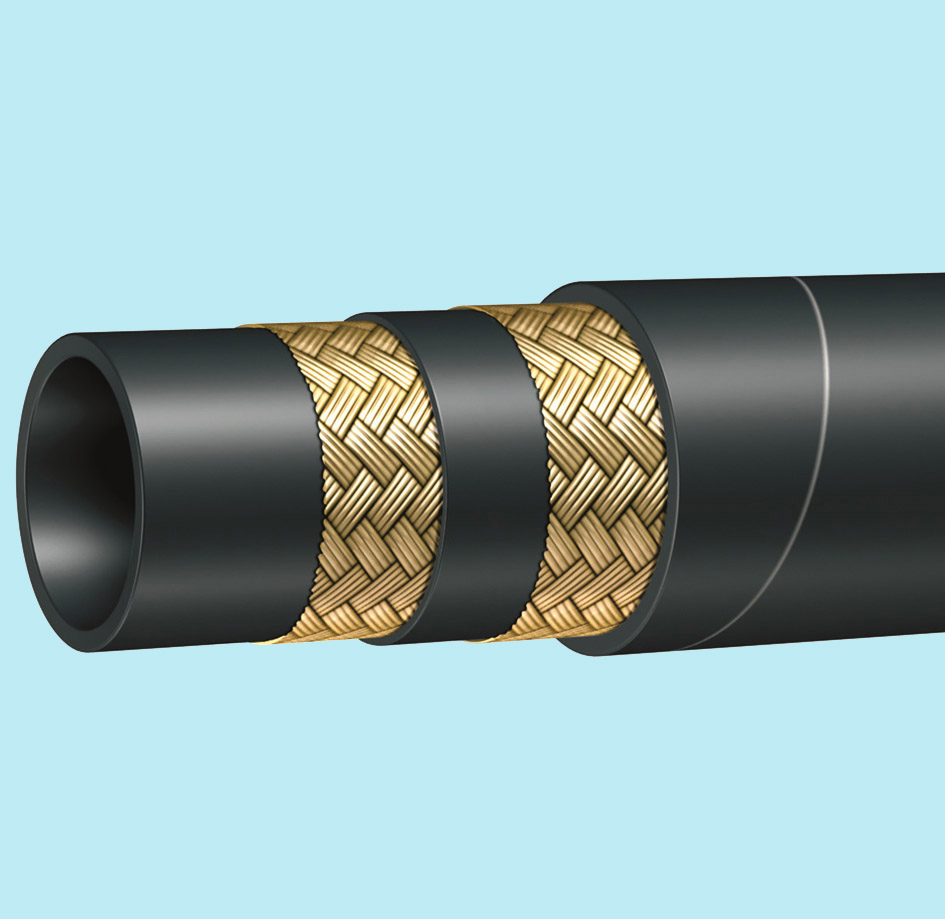

High carbon steel wire, stainless steel wire, electric galvanized & hot dipped galvanized steel wire, ACSR core wire, PC wire & PC strand, tyre bead wire, rubber hose reinforcement brass coated wire, oil hardened & tempered steel wire, low carbon steel wire, steel wire rope, wire drawing machine, tubular stranding & rope making machine, planetary closer and other relevant wire products.

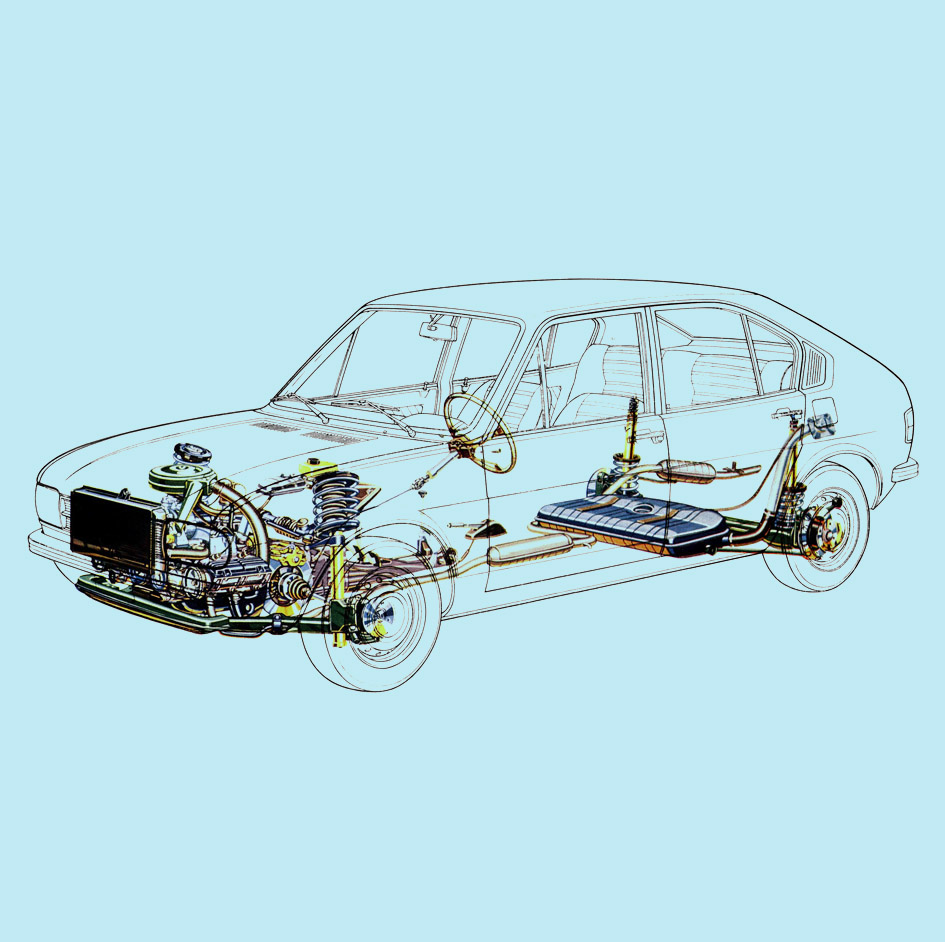

SINCERITY & TRUST

Our core competence is in providing the superior steel wire products with technical support to all companies in the spring, automotive, mechanical, hardware, construction, crane, grid and infrastructure sectors who are using steel wires and ropes as one of their consumables. In addition that, we wholeheartedly help customers to avoid purchase risks, decrease unreasonable costs, advise sound solutions, ensure businesses always achieve satisfaction, and finally promote and keep the partnership & friendship for long-term on the basis of win-win cooperation, mutual respect, manful to duty and heart to heart trust.

SECTORS

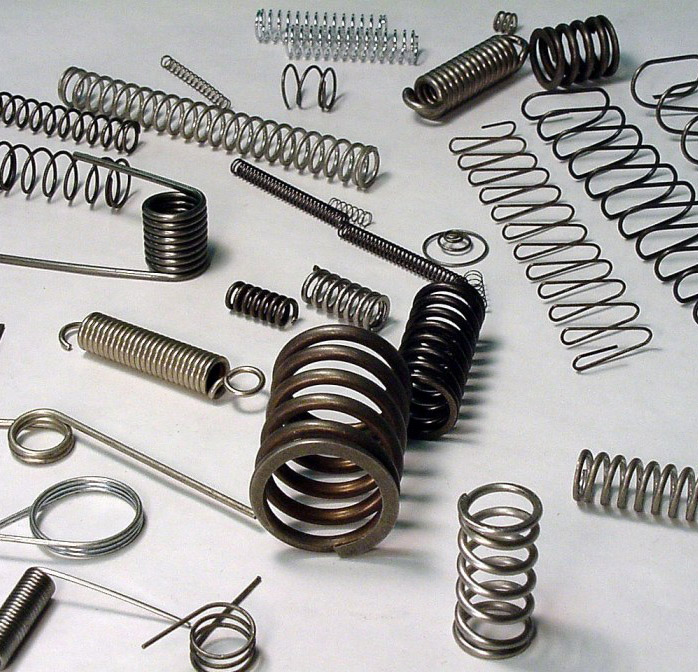

steel wire for spring

Steel wire for automobile

Steel wire for mechanics

Steel wire for bridge

Steel wire for grid

Steel wire for hose

Steel wire for fence

Steel wire rope for aircraft

Steel wire rope for expressway

Steel wire rope for crane

Steel wire rope for lifts

Steel wire rope for car cable